Legislation and standards currently associated with electronic powered gates.

Due to regulation brought to our attention regarding electronic operated gates we are advising you that the Health and Safety Authority are issuing guidelines regarding the safety of electronic operated gates.

The Safety, Health and Welfare at Work Act requires every employer and self-employed to ensure, so far as is reasonably practicable, the design, provision and maintenance of safe means of access to and egress from a place of work, and the design, provision and maintenance of machinery that is safe and without risk to health. The control of hazards from powered gates needs to be addressed in any risk assessments, and safety statements prepared under sections 19 and 20 of this Act.

Hazards and Controls

When identifying hazards and danger zones associated with powered gates, consideration should be given to, among other things, the following:

* Any points where persons may be injured by being crushed or becoming trapped e.g.

> meeting point between swing gates when closing.

- sliding gate at “end of travel” positions.

- trapping of feet between lower edge of gate and ground.

- space between a moving gate and a fixed object and

- contact with moving parts at the drive unit;

* hazards from being caught or hooked by sharp edges or projections;

* the impact forces produced by a gate when it strikes a person or an obstacle;

* hazards associated with the gates being activated automatically, or by another person (for example, by a sensor under the road surface activating a gate when a car drives over it, a remote button, a key fob pressed by a third person or a gate operated by dialling a mobile phone);

* possible ways in which safe operation systems (such as key-pad or key-fob systems) could be defeated, by – passed or inappropriately operated, thereby placing any person at risk. (This is particularly relevant where children, members of the public or persons not familiar with a location have access to powered gates

and may not recognise a risk to their safety);

* possibility of gates becoming detached from their supports and falling over; all danger zones up to a height of 2.5 metres should be identified;

* electrical hazards, such as electric shock or erratic behaviour due to ingress of moisture.hazards from being caught or hooked by sharp edges or projections;

Increased Risk

Factors that can give rise to an increased risk include:

- use by children

- use by infirm or elderly persons,

- unrestricted access or other instances when it is not possible to instruct, train or supervise the gate users,

- high frequency of use or large number of persons passing by or

- a high degree of automation.

Powered gates specific hazards & control measures.

There are two types of powered gates, sliding gates and hinged gates, which will be addressed in detail in this guidance.

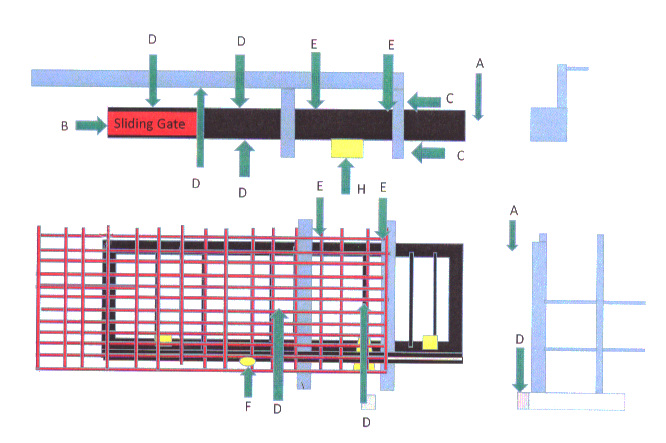

Sliding Gates. Figure 1 shows a plan and elevation view of a sliding gate. Areas A to H show the areas where injury could potentially be caused.

Figure 1 Plan and elevation views of powered sliding gate including hazardous area A- H

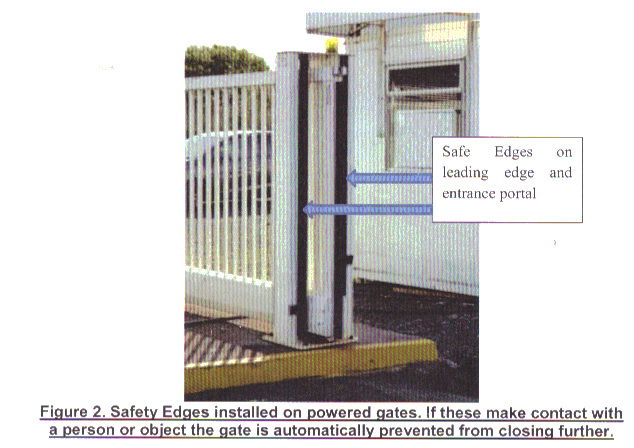

he bullet points A to H describe these hazard and the type of measures needed to control the risk from each hazard. Figure 2 shows how safe edges can be installed to prevent crush and entrapment injuries.

A. Main Closing Edge;- crush and impact hazards controlled by either inherent force control, safety edges, light/radar curtaining or by having the gate hold-to-run.

Inherent force control can be provided by intelligent drive units that cause the gate to reverse when an obstruction is sensed.

Safe edges are sensitive rubber switching strips which, when contact is detected, send a signal to the gate controller to reverse the movement of the gate.

Light/radar curtaining means placing a curtain of light or radar in front of the danger areas. If the curtain is breached while the gate is operating, the gate will reverse its direction. This may be installed to give protection to vehicles primarily but it will also prevent inadvertent contact with pedestrians.

Hold to run means that the gate can only be opened or closed by a person positioned in a safe are, consciously placing continuous pressure on a controller.

B. Main opening edge:- crush (crush hazard exists whenever a leaf closes to within 500mm of a fixed object, impact hazards are present throughout movement) and impact hazards controlled by either:

C. Entrance portal support frame:- shear or draw in hazards controlled by either;

D. All other support frame, leaf or perimeter:- shear and draw in hazards controlled by either:

E. Upper guide/roller draw in hazards:- Controlled by either;

F. Lower cantilever gate rolling gear hazards:- Controlled by either: - see fig. 3

G. Lower tracked gate rolling gear hazards: controlled by: - see fig. 3

H. Drive unit draw in hazards controlled by

Notes:-

The preferred method of protecting risks B, D, E and H is to guard off the entire run-back area of the gate and provide a maintenance hatch for drive unit access.

List A to H is not exhaustive, other examples may exist dependant on design detail.

A. Main Closing Edge;- crush and impact hazards controlled by either inherent force control, safety edges, light/radar curtaining or by having the gate hold-to-run.

Inherent force control can be provided by intelligent drive units that cause the gate to reverse when an obstruction is sensed.

Safe edges are sensitive rubber switching strips which, when contact is detected, send a signal to the gate controller to reverse the movement of the gate.

Light/radar curtaining means placing a curtain of light or radar in front of the danger areas. If the curtain is breached while the gate is operating, the gate will reverse its direction. This may be installed to give protection to vehicles primarily but it will also prevent inadvertent contact with pedestrians.

Hold to run means that the gate can only be opened or closed by a person positioned in a safe are, consciously placing continuous pressure on a controller.

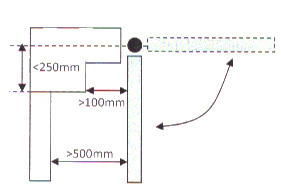

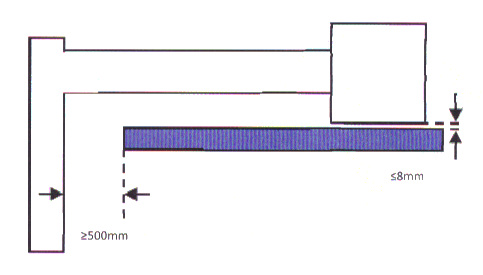

B. Main opening edge:- crush (crush hazard exists whenever a leaf closes to within 500mm of a fixed object, impact hazards are present throughout movement) and impact hazards controlled by either:

- Guarding

- Safety distances – see fig 4

- Inherent or safety edge derived limitation of forces

- Hold to run light/radar curtaining

C. Entrance portal support frame:- shear or draw in hazards controlled by either;

- Safety distances –

- Safety edges – See fig 2

D. All other support frame, leaf or perimeter:- shear and draw in hazards controlled by either:

- Guarding

- Safety edges –

- Hold to run or Light/radar curtaining

E. Upper guide/roller draw in hazards:- Controlled by either;

- Guarding

- Hold to run or Light/radar curtaining

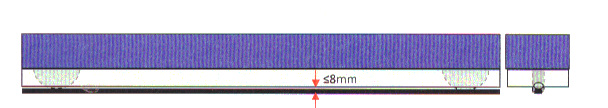

F. Lower cantilever gate rolling gear hazards:- Controlled by either: - see fig. 3

- Internal rollers via lower edge slot – no further risk

- External or exposed rollers – guard

G. Lower tracked gate rolling gear hazards: controlled by: - see fig. 3

- Guard to within 8 mm of ground –

H. Drive unit draw in hazards controlled by

- Guard

Notes:-

The preferred method of protecting risks B, D, E and H is to guard off the entire run-back area of the gate and provide a maintenance hatch for drive unit access.

List A to H is not exhaustive, other examples may exist dependant on design detail.

Figure 3 Guarding of base of powered gate is less than or equal to 8 mm

Figure 4 Gaps at age end-stopping position (when opened) should be as shown, to prevent crushing. Alternatively this area should be guarded.

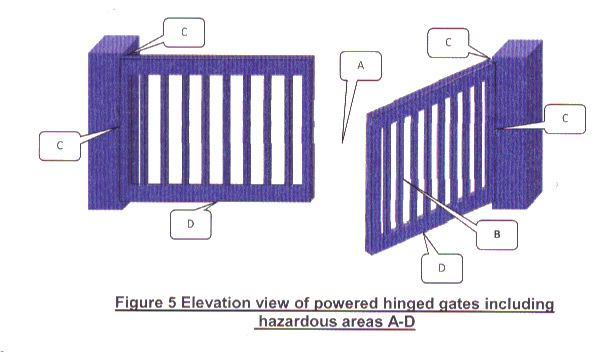

Hinged power gates – Hinged gates have some similar hazards to sliding gates, however the fact that the gates swing open and closed presents some other hazards that must also be considered.

A. Main Closing edge crush and impact hazards controlled by either;

(Opening crush hazards exist wherever a leaf opens to within 500mm of a fixed object, impact hazards are present throughout movement)

- Inherent or safety edge or limitation of forces both in combination with photoelectric beams on the closed face

- Hold to run or light/radar curtaining

(Opening crush hazards exist wherever a leaf opens to within 500mm of a fixed object, impact hazards are present throughout movement)

- Safety distances, for the crush element only – see fig.6/7

- Inherent or safety edge limitation of forces

Figure 6 Safety distances to reduce crushing hazard

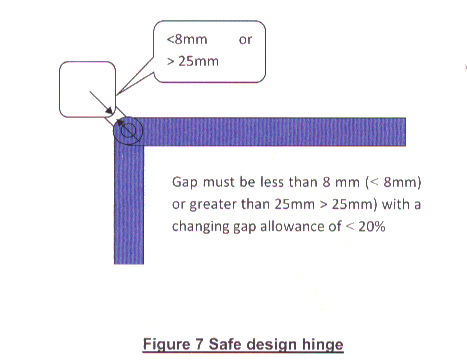

C. Hinge area crush, draw in or shear hazards controlled by;

Maximum gap of 100 mm allowed in all circumstances

> Hold to run or light/radar curtaining

Maximum gap of 100 mm allowed in all circumstances

- Safe design hinges – see fig. 7

- Guards

> Hold to run or light/radar curtaining

Note:-This list is not exhaustive, other examples may exist dependent on design detail, nonetheless, all hazards must be revealed by assessment and controlled.

Overview of Safety measures

An overview of the measures which may help to reduce risk include:

Overview of Safety measures

An overview of the measures which may help to reduce risk include:

- Controlling separation distance between fixed and moving parts to reduce hazards from crushing, shearing and drawing-in points

- Creating safety distances, e.g., ensuring adequate distance between the control panel and the nearest danger point on the gate so that the user is not in a dangerous position and persons cannot reach through a gate to operate a control panel on the other side,

- Installing guards, e.g., a fixed guard to cover mechanical trap points such as guide rollers or sprocket drives;

- Provision of leaf surfaces that are smooth and free of parts that protrude which could catch peoples clothing;

- operating the gate in hold-to-run mode;

- limiting the forces, e.g., protective built into the drive system;

- installing sensitive protective equipment such as pressure sensitive strips (safety edges, safety sensor flooring, light/ radar curtains and photoelectric beams.

- In order to achieve an acceptable level of safety, a combination of the above approaches or measures may be necessary.

- The gates should also reverse if they inadvertently hit someone or something, and the gates should have an emergency release mechanism in case someone gets trapped.

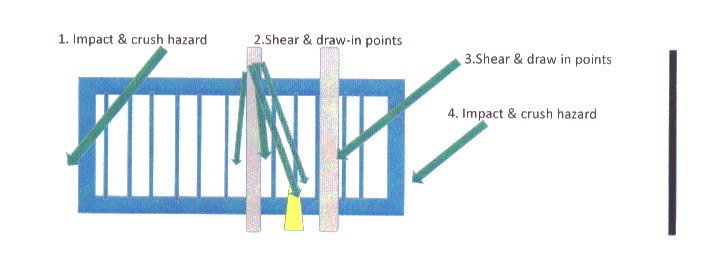

Figure 8 Risk areas associated with powered slidng gates

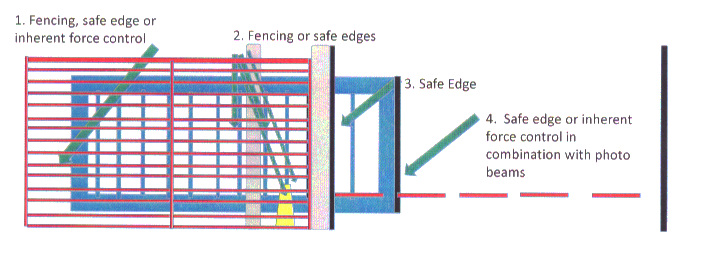

Figure 9 Control Measures to protect users and members of the public

Duties of Gate Owners – Commercial/Professional /Private

Commercial property owners, landlords or facilities managers of properties with powered gates, have duties under the Safety, Health and Welfare at Work Act, to ensure the safety of people using or in the vicinity of such gates. They have a responsibility to ensure that their staff, and other workers, visitors or members of the public are not put at risk by the gate’s design, construction, operation or lack of maintenance. The control measures will include some of those outlined in the section on Hazards and Controls. All gate owners must consider acquiring the services of a reputable company, contractor or competent person familiar with the requirements of the Machinery Regulations and relevant European Directives and Standards to assist them with their risk assessment obligations. The gate, as an item of work equipment, must be kept, by means of adequate maintenance, at such a level that it is safe for use.

The gate should be regularly maintained by a reputable company, which maintenance should include a test of the safety features of the gate to ensure they are set and working correctly and a test of the closing forces.

The test of the closing forces requires the use of measuring equipment and the tester should be competent in the use of such equipment. A log should be kept of the maintenance and testing.

The owner should ask the gate maintenance company to demonstrate how to release the gate in an emergency – this should be easy and quick to do. There may also be a need to inform other users how to do this.

The owner should also be familiar with the safety features of the gate, including:-

- Any safety edges ( usually rubber “buffer” strips running the full height of the gate);

- Light beams, or others sensors, to detect a person or object in the way of the closing gate;

- The operation of the force limitation device (although this is unlikely to be enough to stop injury on its own);

- Fixed guards at other areas e.g. where the vertical bars of the gate slide close to the vertical bars of a fence.

Again, a reputable company should be able to illustrate and explain the safety features.

Actions by an owner.

An owner of a powered gate who may have concerns about the safe operation of any powered gate should not use the gate until the gate is examined by a competent person who is familiar with the requirements of the Regulations and relevant European Directives & standards.

We would recommend that the following are checked now by a qualified installer to ensure that your electronic gate is safe to use.

Carry out a check of the following:

- The motors operate smoothly and without unusual noise such as banging.

- The gate and gate posts are without fault, pay particular attention to the hinges.

- The control panel casing is without fault and sealed correctly.

- Safety cells operate correctly on opening cycle.

- Safety cells operate correctly on closing cycle.

- All remote controls and other activation accessories (such as keypads) work correctly.

- The opening path of the gate is free from obstructions.

- Check that all wiring is correctly ducted and not exposed to the elements.

- The gate has a completed CE conformity plate attached.

- All safety accessories installed work correctly to their designed function.

- Check that there are no crush points where people can be hurt.

- Safety edges are fitted and working correctly to any point where a person may get hurt or crushed.

- Installations must be serviced at regular intervals according to usage, a correctly completed maintenance record must be provided, a minimum maintenance scheme must be considered as the following for all applications;

- Systems used up to 20 uses per day should be serviced once every 12 months.

- Systems used up to 20 to 50 times per day should be serviced every 6 months.

- Systems used over 50 times per day should be serviced every 3 months.

If any of the above items are damaged, missing, incomplete or not operating properly we would advise that do not use your electronic operated gate until a qualified installer inspects the gate as you may be putting yourself or others at risk of injury.

If you want a competent company to check your gate please contact us on 056 7767138/086 2790225 Leslie Byrne.

There will be a charge of €100.00 + VAT to inspect your electronic powered gates and give a safety report.

Please do not hesitate to contact us on email [email protected].